Interested in learning more? View detailed specifications and features of the NANOFABRICATOR™ LITE. Let’s discuss how NANOFABRICATOR™ LITE can support your unique research goals

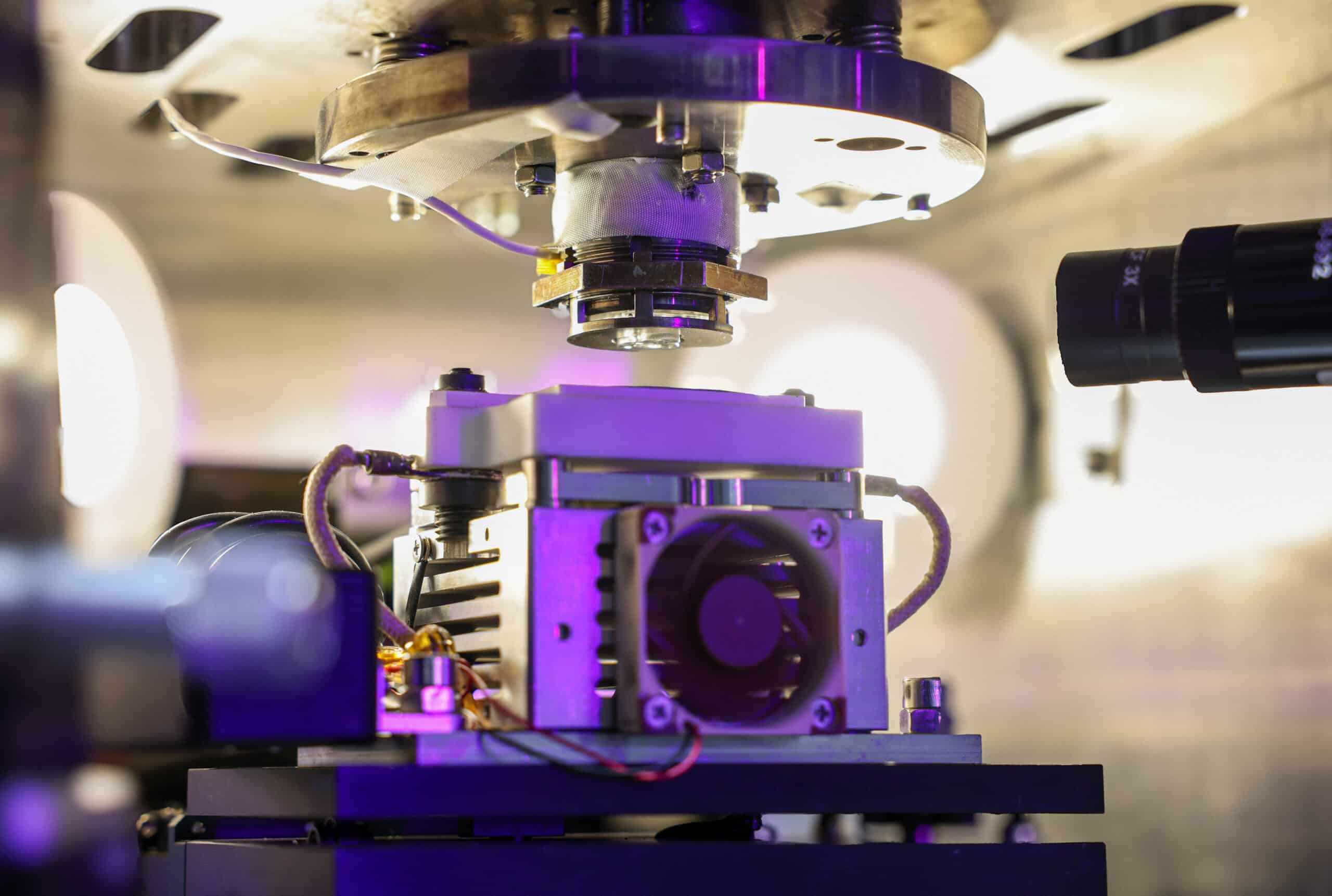

Our vision is to pioneer the next frontier in manufacturing technology, achieving atomic-level precision in the creation and assembly of advanced materials and components. We aim to establish a groundbreaking infrastructure dedicated to the development and production of micro and nanoelectronics, as well as optics and photonics, both on Earth and in extraterrestrial environments. In this endeavor, we will push the boundaries of current technology, enabling the construction of devices and systems that are not only smaller and more efficient but also more powerful and versatile than anything existing today. Our focus extends to revolutionizing the way we think about and interact with technology, opening up new possibilities in computing, communication, healthcare, and environmental monitoring. Vision & Mission with Maksym Plakhotnyuk, the CEO & Founder of ATLANT 3D. We’ve seen firsthand how DALP® technology transforms research and manufacturing across different sectors: University researchers use our platform to test multiple material combinations simultaneously, generating up to 50 data points in a single run rather than spending weeks on individual tests. This capability is especially valuable for teams working on quantum computing materials, advanced sensors, and novel semiconductor compounds. R&D teams in industry have streamlined their prototyping process, eliminating complex multi-step fabrication sequences. Our technology allows direct patterning with different materials on various substrates—including metals, semiconductors, and dielectrics—significantly reducing the time from concept to functional prototype. Manufacturing specialists are discovering more sustainable production methods through our localized, targeted approach that deposits materials precisely where needed. By reducing waste We see DALP® technology as the foundation for a new era in manufacturing—one where precision at the molecular scale becomes accessible to more researchers and industries. Beyond just making existing processes faster, we’re enabling entirely new classes of materials and devices: from quantum computing components to specialized sensors that can function in the vacuum of space. Our work with NASA and the European Space Agency has demonstrated that this technology can operate beyond Earth, potentially supporting manufacturing in space and on other planets. What began as a concept supported by three European universities—Technical University of Denmark, Institute of Electrical Engineering Slovak Academy of Sciences, and Friedrich Alexander University Erlangen-Nuremberg—has evolved into technology that’s being adopted by leading research institutions and companies worldwide. We’ve been fortunate to receive recognition from organizations like Hello Tomorrow and the Royal Society of Chemistry. But what truly matters to us is seeing what researchers and manufacturers create with our technology. Each breakthrough achieved by someone using our platform adds another chapter to our story—and reminds us why we started this journey in the first place. The ATLANT 3D Story

Redefining Manufacturing

Our mission

We are building the future atomically precise advanced manufacturing technology and infrastructure for micro and nanoelectronics, optics and photonics on Earth and Beyond.

Who Benefits From Our Work

Our story

The Future is ATLANT 3D

Funded by

Awards & Recognition

Transform your research today

Nik Thorsen

Business Development Manager