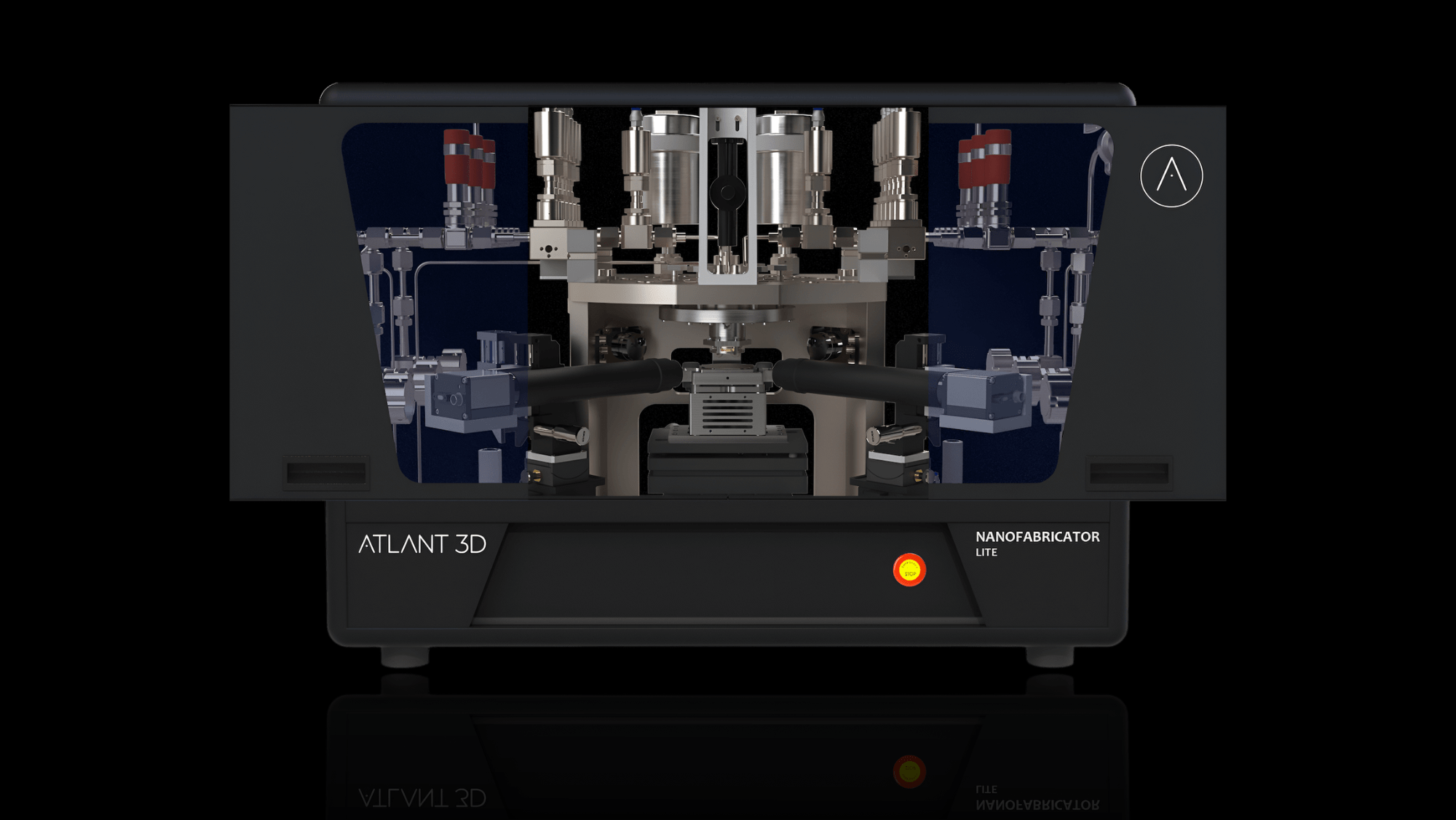

We invite you to experience the NANOFABRICATOR™ LITE and its capabilities in action – from atomic scale thickness variability to multi-cycle and multi-material deposition. Our team of highly skilled engineers and scientists with extensive expertise in material and process R&D, advanced application development and system engineering are here to help with any questions you may have. Our services include feasibility studies for validating R&D concepts, proof of technology projects to meet technical requirements, and customized R&D prototyping for innovative engineering solutions. We support your unique challenges and ideas at every stage. We enable on-demand next-generation microdevices printing on simple and complex surfaces atom-by-atom. Trusted by * Dependent on materials to be deposited and customer needs. ** Additional number of bubblers and reactants dependent on customer needs. *** Additional reactant types dependent on customer needs. **** Clean room, CLASS 8 min recommended. ***** Argon recommended. Book a demo

SEND US A MESSAGE

EXPERIENCE ATOMIC PRECISION

Contact our team to book a demo.

DALP™ Technology

REDEFINING MICROFABRICATION

MEMS and Integrated Sensors, Microfluidics and Lab-on-Chip, RF-devices, Optical and Photonic Devices, Quantum and Energy-Harvesting/Storage Devices can be developed with ATLANT 3D technology with previously impossible functionality and speed at a fraction of a cost.

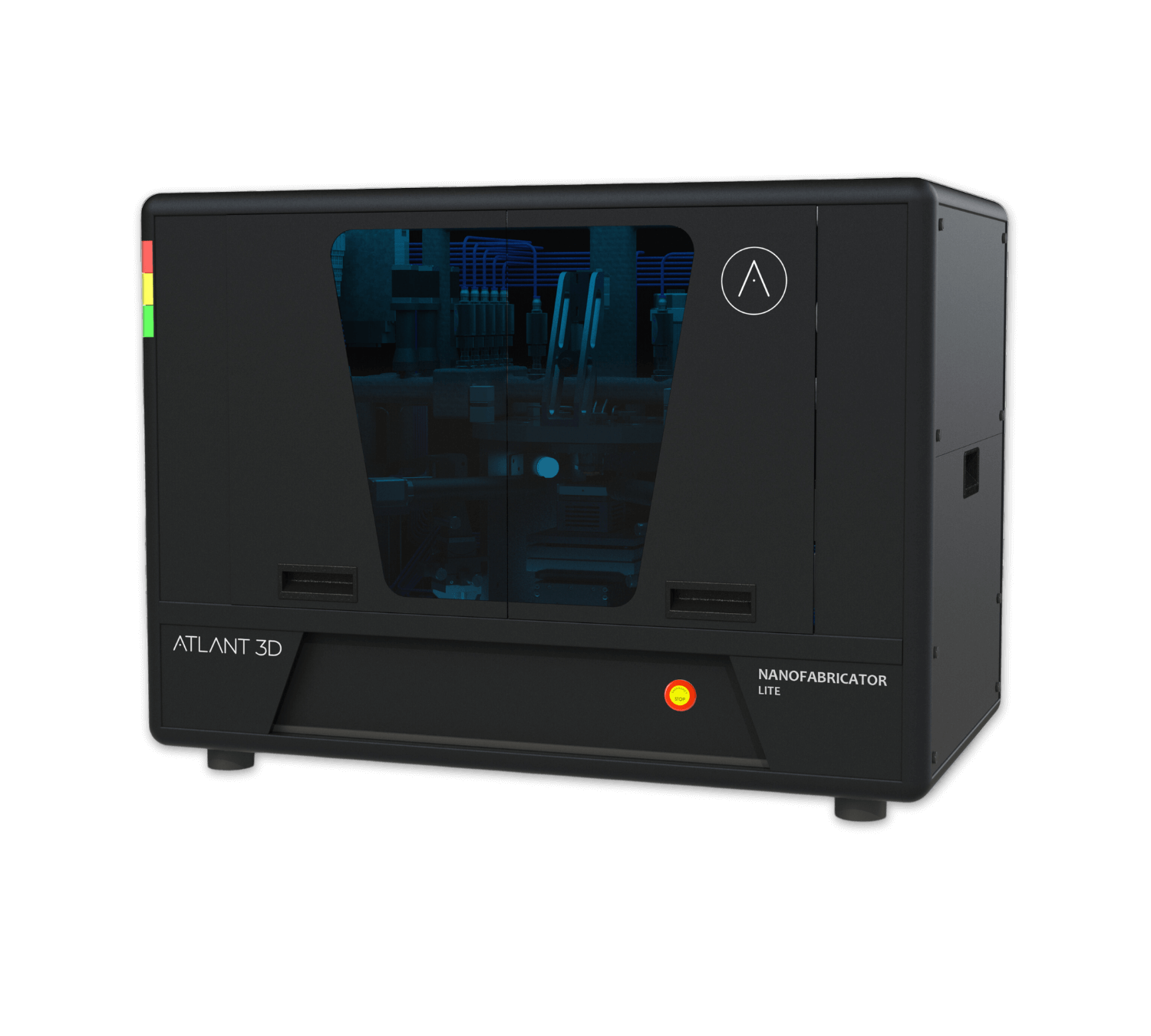

NANOFABRICATOR™ LITE

Technical Specification

Substrate

Process Chamber

Gas system

Options

- Technology

OUR TECHNOLOGY

TechnologyDiscover ATLANT 3D's unique atomic layer advanced manufacturing technology based on Direct Atomic Layer Processing (DALP®).

- Solutions

OUR SOLUTIONS

All ProductsOur revolutionary tools are built to enhance the whole value chain of advanced micro- and nano-device manufacturing. Our A-HUB solutions enable rapid prototyping, pilots and feasibility studies.

- Applications

ADVANCED NANOFABRICATION

All ApplicationsOur technology is built for advanced applications enabling previously impossible functionality and speed at a fraction of the cost. Its reach across multiple application domains plays a pivotal role in propelling industries toward cutting-edge technological achievements.

- Insights

INSIGHTS

Explore insightsLearn how we are building the foundation for new advanced materials innovation and high-tech applications of the future.

RESOURCES

- About

OUR MISSION

About UsWe are building the future atomically precise advanced manufacturing technology & infrastructure for micro and nanoelectronics, optics & photonics on Earth and Beyond.

OUR COMPANY