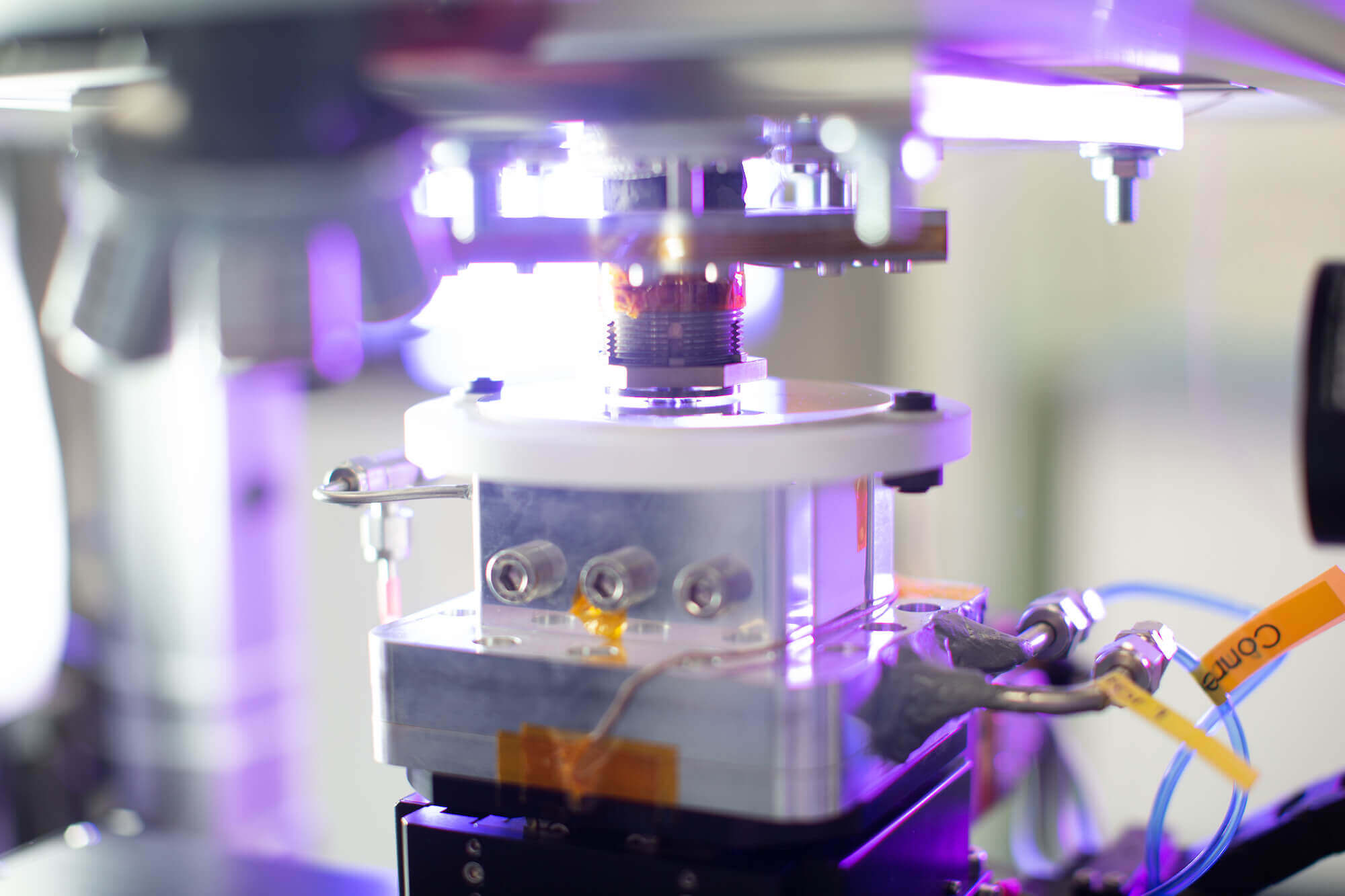

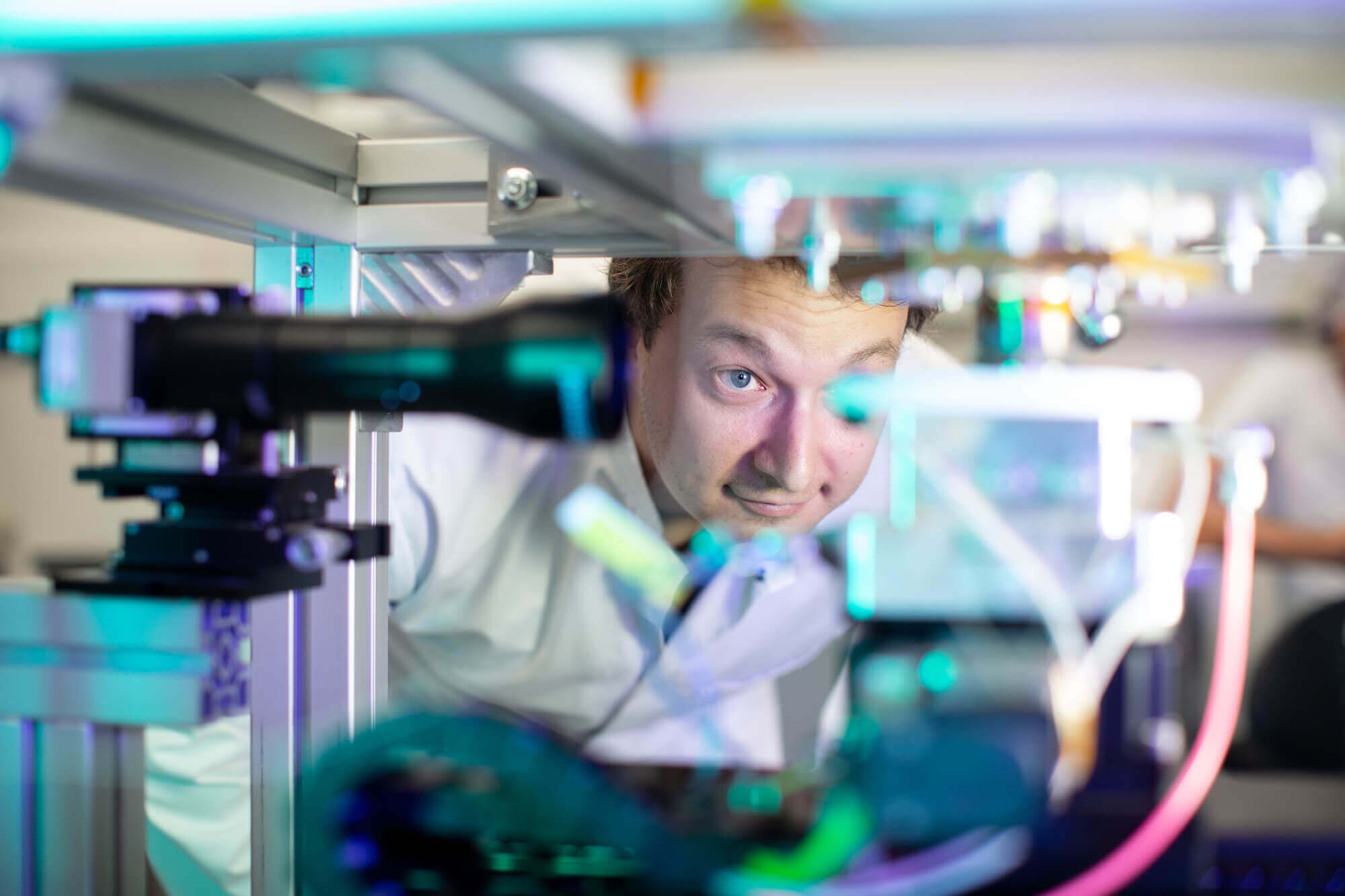

First ever on-demand atomic layer advanced manufacturing technology based on hybrid Microreactor Direct Atomic Processing. We enable on-demand next-generation microdevices printing on simple and complex surfaces atom-by-atom. The NANOFABRICATOR™ LITE is the most compact tool ever created to accelerate materials, processes and device innovation with atomic precision. It is suitable for a wide range of applications such as MEMS, devices, optics, photonics, packaging, RF & electronics and quantum devices which can be developed with ATLANT 3D technology with previously impossible functionality and speed at a fraction of a cost. ATLANT 3D’s Direct Atomic Layer Processing (DALP®) has revolutionized prototyping, turning a traditionally lengthy process into a rapid, precise operation. Key benefits include accelerated development cycles, atomic-level control for complex prototypes, versatile material and surface adaptability, and cost reductions due to increased efficiency. This advancement in DALP® fosters a conducive environment for innovative microdevice fabrication, marking a significant leap in microfabrication technology. We developed μDALP™ (Microreactor Direct Atomic Layer Processing/Printing) patent-pending technology that provides highly conformal, direct material writing, and removal with atomic precision and material versatility. ATLANT 3D’s technology involves the sequential deposition of gasses for atomically precise patterning of various materials.So far we tested with our technology the following materials: TiO2, Pt, ZnO, SiO2. And it is continuously updated. Our DALP™ technology allows to print conformally different materials, enabling: Our technology allows unprecedented selective patterning on flat, corrugated and porous surfaces: The evolution of Atomic Layer Processing has been marked by a significant transition, primarily spearheaded by ATLANT 3D’s innovative DALP® technology. This paradigm-shifting advancement redefines the precision and control achievable in thin-film deposition. By facilitating atomic-scale manipulation within the fabrication process, DALP® introduces an enhanced level of granularity and uniformity in material layering. This breakthrough is indicative of a broader trajectory within materials science, driving towards miniaturization and enabling the complex device architectures necessary for next-generation technologies. Sequential pulse sequence for precursor and co-reagent delivery. Time base separation of reagents. TALD is the traditional form of ALD, known for its sequential exposure of surface substrates to precursor vapors, each separated by an inert gas purge to prevent gas-phase reactions. TALD’s strength lies in its exceptional conformality and thickness control, making it ideal for high-quality thin-film coatings. However, TALD’s reliance on vacuum environments and time-consuming purge steps often results in slower deposition rates, which can be a limiting factor for large-scale and rapid manufacturing needs. Spatial separation of precursor and co-reagent with increased deposition speed. Physical distance separation of reagents. SALD, an evolutionary step from TALD, maintains the self-limiting surface reactions characteristic of ALD while enhancing throughput. By spatially separating the precursors, SALD systems deposit materials at atmospheric pressure, significantly increasing the deposition rate. SALD is adaptable to roll-to-roll processes, making it attractive for large-area coatings. Nevertheless, SALD’s dependency on sophisticated equipment to maintain precursor separation can complicate system design and scalability. ATLANT 3D’s Direct Atomic Layer Processing (DALP®) technology represents a seminal breakthrough in the atomic layer deposition (ALD) arena. By ingeniously combining the meticulous precision of Temporal ALD (TALD) with the accelerated deposition rates characteristic of Spatial ALD (SALD), DALP® stands as a beacon of innovation, all while operating in ambient atmospheric conditions. This remarkable synthesis of speed and accuracy in DALP® is made possible through a distinctive microreactor design, which enables the direct application of precursor molecules onto the substrate, negating the need for vacuum environments that have long been a staple of ALD processes. The Direct Atomic Layer Processing (DALP™) technology has been rigorously tested with a variety of Atomic Layer Deposition (ALD) materials. These materials have been chosen for their unique properties and applications in various high-tech industries. The tested ALD materials with DALP® demonstrate the technology’s versatility and efficiency in handling diverse substances, ensuring precision and consistency in the deposition process. This extensive testing underscores DALP® potential in revolutionizing material processing in microfabrication and nanotechnology fields. Used for its photocatalytic properties and UV absorption, common in sensors and solar cells. Offers semiconducting, piezoelectric, and pyroelectric properties, ideal for electronic and optoelectronic devices. A highly conductive and corrosion-resistant metal, often used in electronic components and catalytic applications. Known for its hardness and thermal stability, used in insulating layers and as a barrier material. A p-type semiconductor with applications in batteries, solar cells, and gas sensors. A highly dense and corrosion-resistant material, used in high-temperature and harsh environmental applications. Known for its electrochemical stability, used in electrodes and corrosion-resistant coatings. Exhibits high dielectric constant and stability, used in semiconductor gate insulators and optical coatings. The selected ALD materials, each with unique properties, affirm DALP’s applicability across multiple domains, including semiconductor manufacturing, energy storage, and nanoelectronics. At ATLANT 3D, we are not just changing how things are made; we are redefining the principles of manufacturing. Our commitment to sustainability is a testament to our belief that responsible innovation and business practices can create a positive impact on the world, paving the way for a more sustainable future in manufacturing and beyond. Sustainability is integral to our mission. We believe that the future of manufacturing must not only be innovative and efficient but also environmentally conscious. Our technologies are designed to reduce waste, lower energy consumption, and minimize the environmental footprint of manufacturing processes. By prioritizing sustainable practices, we aim to lead by example, showing that technological advancement and environmental stewardship can coexist harmoniously. Microelectronics are essential components in a wide range of products, from consumer electronics to medical devices. However, traditional manufacturing methods for microelectronics are often energy-intensive and produce significant waste. ATLANT 3D offers a new approach to microelectronics manufacturing that is more sustainable and environmentally friendly. Our revolutionary tools are built to enhance the whole value chain of advanced micro- and nano-device manufacturing. ATLANT 3D redefining the landscape of advanced manufacturing with its pioneering NANOFABRICATOR™ series. It enables multi-material deposition in one process, tested on a wide range of advanced materials, independent of surface roughness and substrate sensitivity with multi-shape deposition and a high degree of thickness control. Find insights into our Microreactor Direct Atomic Processing (DALP®) and other advanced technological developments. Here we explains our pioneering nanofabrication methods, their applications, and advantages in the realm of atomic-scale manufacturing. DALP® TECHNOLOGY

Unique technology

REDEFINING MICROFABRICATION

Advanced Microfabrication

Rapid, Precise, & Versatile Atomic Processing

Innovation

Efficiency

Materials

DALP™

GAS DEPOSITION

MULTISTACK PRINTING

COMPLEX SURFACES

Paradigm-shifting technology

EVOLUTION OF ATOMIC LAYER PROCESSING

TEMPORAL ALD

SPATIAL ALD

DALP® DIRECT ATOMIC LAYER PROCESSING

Materials

ALD MATERIALS TESTED WITH DALP®

MATERIAL

TiO2 DALP® tested

MATERIAL

ZnO DALP® tested

MATERIAL

Pt DALP® tested

MATERIAL

Al2O3 DALP® tested

MATERIAL

CuO DALP® tested

MATERIAL

Ir DALP® tested

MATERIAL

IrO2 DALP™ tested

MATERIAL

HfO2 DALP® tested

Sustainability

Setting New Benchmarks in Sustainable Manufacturing

NANOFABRICATOR™ Series

Our Solutions

Questions & Answers

- Technology

OUR TECHNOLOGY

TechnologyDiscover ATLANT 3D's unique atomic layer advanced manufacturing technology based on Direct Atomic Layer Processing (DALP®).

- Solutions

OUR SOLUTIONS

All ProductsOur revolutionary tools are built to enhance the whole value chain of advanced micro- and nano-device manufacturing. Our A-HUB solutions enable rapid prototyping, pilots and feasibility studies.

- Applications

ADVANCED NANOFABRICATION

All ApplicationsOur technology is built for advanced applications enabling previously impossible functionality and speed at a fraction of the cost. Its reach across multiple application domains plays a pivotal role in propelling industries toward cutting-edge technological achievements.

- Insights

INSIGHTS

Explore insightsLearn how we are building the foundation for new advanced materials innovation and high-tech applications of the future.

RESOURCES

- About

OUR MISSION

About UsWe are building the future atomically precise advanced manufacturing technology & infrastructure for micro and nanoelectronics, optics & photonics on Earth and Beyond.

OUR COMPANY