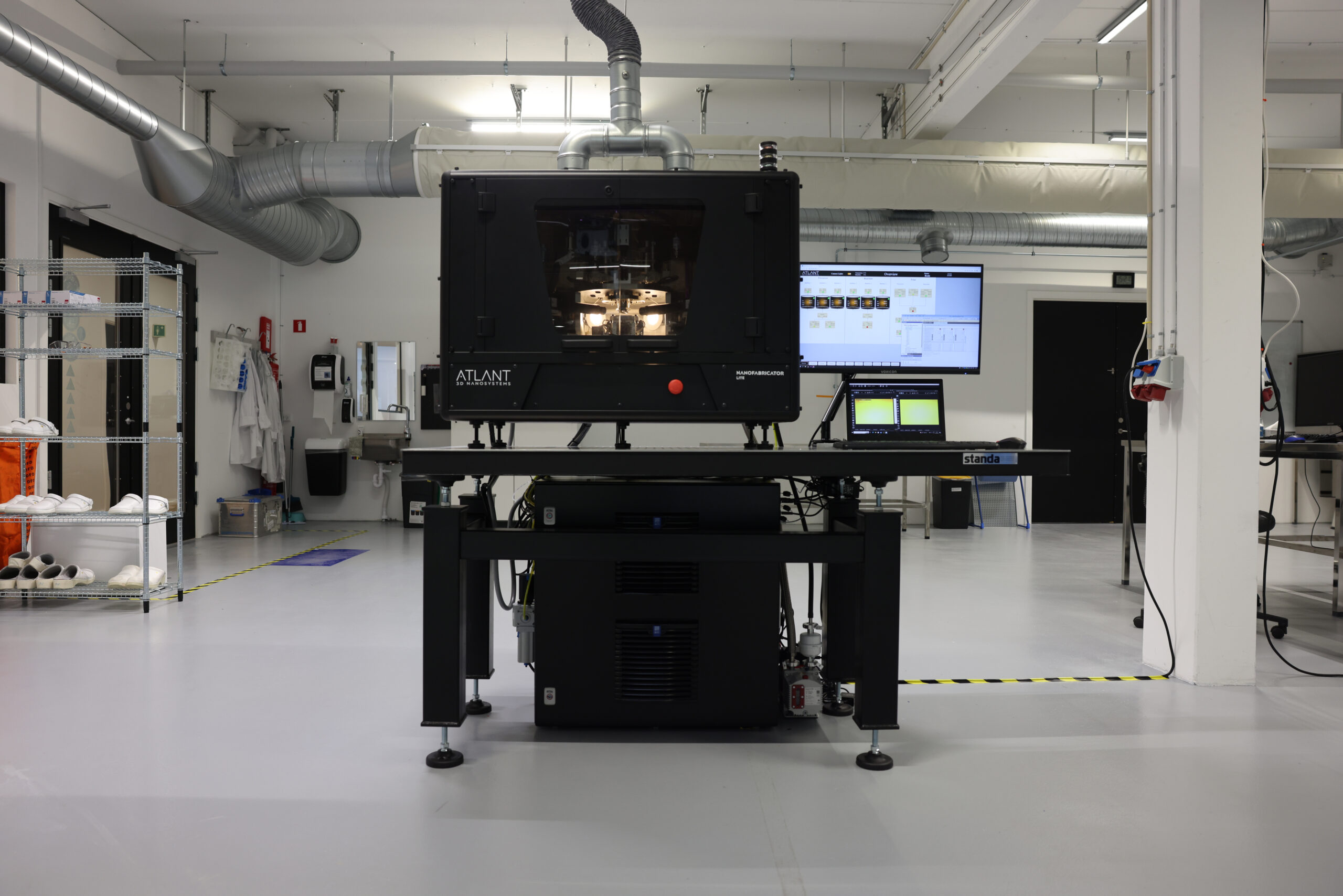

As semiconductor architectures evolve and packaging demands intensify, traditional fabrication methods face increasing constraints. Direct material processing at the atomic level enables both sophisticated IC development and advanced system integration. Al₂O₃, HfO₂, TiO₂ Pt, Ir, IrO₂ ZnO, SnO₂, Ga₂O₃ Nb₂O₃ for energy storage Glass, Fused silica, Polymers – Precise additive and subtractive processing – Next-generation dielectric barriers Advanced packaging & semiconductor

Advanced packaging & semiconductor

From Silicon to System: A New Approach

Beyond the Boundaries

of Traditional Processing Advance Semiconductor

Development

Master System

Integration

Process Control

Material Systems

Platform Compatibility

Research Outcomes

System Capabilities

– Selective area deposition

– Multi-material sequential integration

– High-quality crystalline growth

– Custom gradient structures Validated Applications

– Power electronic components

– Complex heterogeneous devices

– Advanced interconnect architectures

– Novel semiconductor structures

Explore Technical Possibilities

Nik Thorsen

Business Development Manager