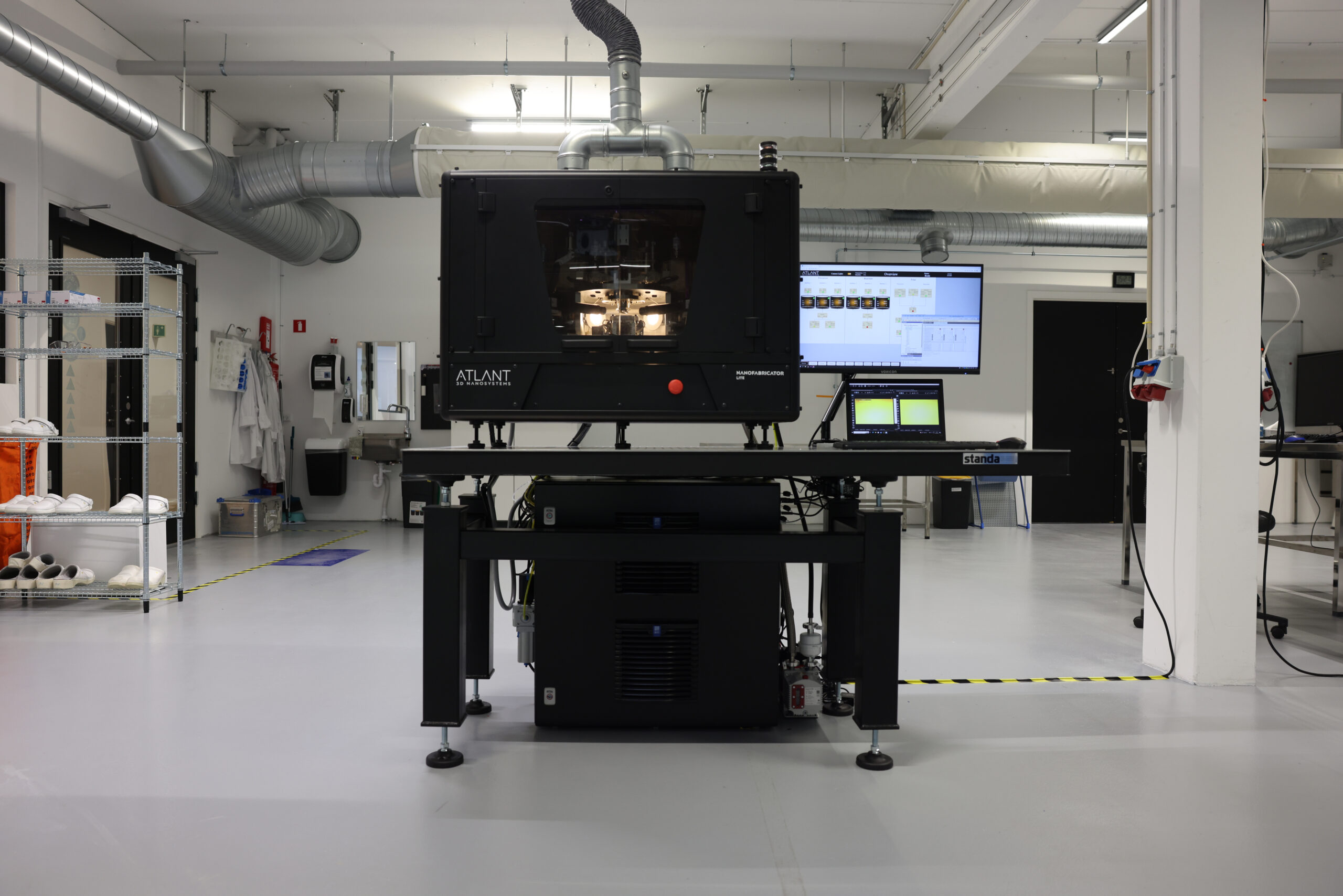

In both biotechnology research and medical device development, the ability to control material properties at the molecular level opens new possibilities. From lab-on-chip devices to advanced implant coatings, precise material integration enables next-generation bio-interfaces. Fused silica, Borosilicates – Direct material patterning – Lab-on-chip devices Biotech & Medical Devices

Biotech & Medical Devices

Design at the Scale of Life

Beyond the Boundaries

of Traditional Processing Transform Biotechnology

Research

Enhance Medical

Device Design

Process Control

Material Systems

Platform Compatibility

Research Outcomes

Process Capabilities

– Selective area deposition

– Multi-material integration

– Gradient formation

– Conformal coating in structures up to 60µm Research & Development Areas

– Biosensor platforms

– Anti-bacterial surfaces

– Protective medical coatings

– Advanced diagnostic systems

Discuss Your Research Requirements

Nik Thorsen

Business Development Manager