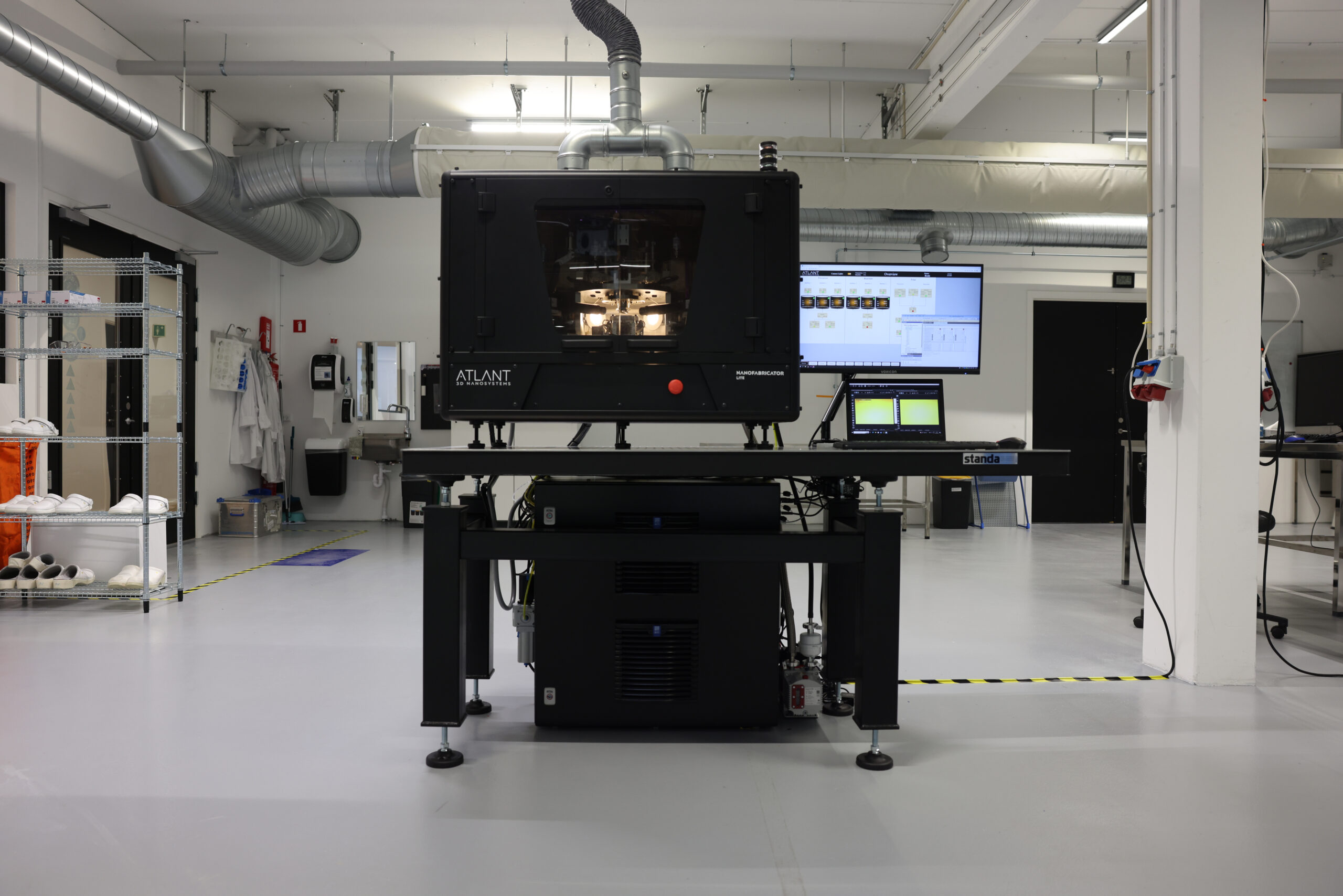

Precision-driven microfabrication for enhanced sensory technologies.

MEMS & Sensors

Unlock New Possibilities in MEMS & Sensor Development

Traditional MEMS and sensor manufacturing faces significant challenges in achieving uniform thin-film deposition on complex 3D structures.

Issues like stiction, material durability, and performance limitations under extreme conditions slow innovation and increase costs.

Precision Engineering

Meets Practical Innovation

Master Materials

at the Molecular Level

- Investigate functional materials for MEMS applications (piezoelectric

- ferroelectric

- magnetic

- thermal-responsive)

- Develop specialized coatings for nanoparticles and nanorods

- Create both nanoparticles and dense layers

- Ensure complete material compatibility with existing MEMS fabrication

Turn Concepts

into Reality Faster

- Integrate with standard process flows

- Create novel sensor designs for enhanced sensitivity

- Optimize multi-layer architectures

- Achieve seamless integration on complex surfaces

Build What

Others Can’t

- Local deposition of sensors on complex geometries

- Prototype environmental sensors (ions

- gas

- temperature

- pressure)

- Design experiments to optimize material properties

- Enable compact integration into single platform

- Provide local encapsulation of sensing elements

Engineering at the Edge of Possibility

- Processing temperature range: Room temperature to 300°C

- Current line width: 400 µm (25 µm in development)

- Variable process speed: 0.1 mm/s to 100 mm/s

- Conformal deposition depth: Up to 60 µm

- Material library: 450+ ALD materials

Your Material Palette

ZnO, TiO2, SnO2, V2O5, Ga2O3, CuO

Build on Any Foundation

- Silicon

- SiC

- GaN wafers

- Glass

- Fused silica

- Borosilicates

- Polymers

Let’s Create Something Extraordinary

Contact our applications team to discuss your specific needs and discover how atomic-layer processing can advance your MEMS and sensor projects.

Nik Thorsen

Business Development Manager