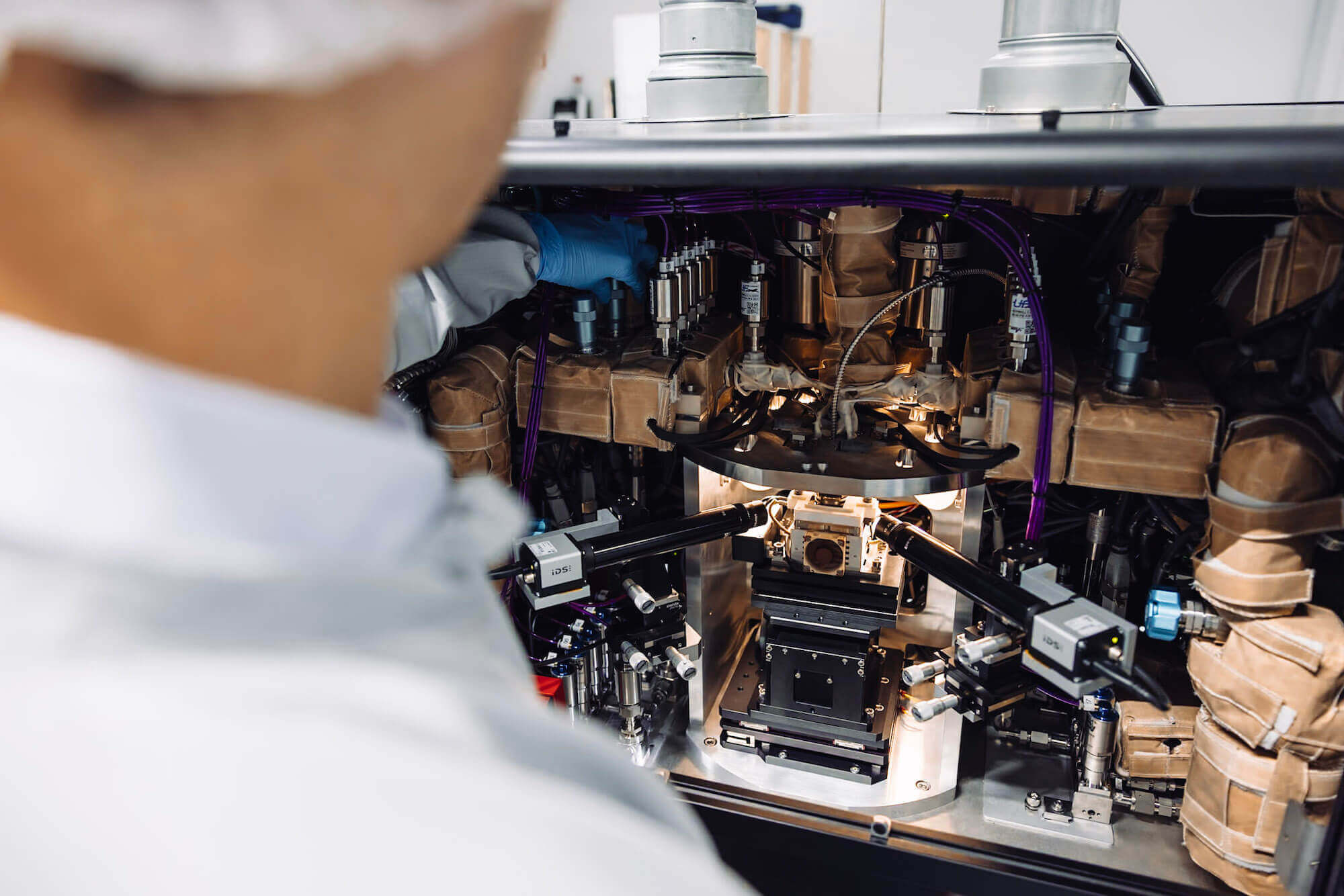

Research and collaborative space for groundbreaking innovations in micro- and nanotechnology. A-LAB envisions a future where the barriers to advanced microfabrication are dismantled. Our aim is to accelerate the development of cutting-edge technologies and materials, contributing significantly to fields like electronics, biotechnology, and renewable energy. A-LAB is dedicated to sustainable and responsible research practices that benefit both industry and society. Engaging with A-LAB is an opportunity to be at the forefront of microfabrication research. We invite you to explore the potential of collaborating with us, whether your interest lies in exploring new materials, developing advanced microdevices, or pushing the boundaries of current technological capabilities. Direct Atomic Layer Processing (DALP®) represents the core of ATLANT 3D’s innovation. This cutting-edge technology enables unprecedented precision in micro and nanofabrication. DALP® allows for the manipulation of materials at the atomic level, leading to groundbreaking advancements in material science and electronics. Our expertise in atomic layer processing ensures that we can build devices and components with unmatched accuracy and efficiency. A-LAB, situated within A-HUB, is our state-of-the-art research and development facility. Here, we conduct pilot and joint development projects with clients, pushing the boundaries of atomic layer processing and microfabrication. A-LAB represents our commitment to innovation and continuous improvement, making it an attractive proposition for investors interested in cutting-edge research and technological advancement. At the core of A-LAB is a collaborative and experimental approach to R&D. Leveraging our proprietary DALP® technology and advanced NANOFABRICATOR™ devices, we engage in a range of projects from feasibility studies to comprehensive research endeavors. Our process is meticulously designed to foster innovation at every stage, ensuring precision, efficiency, and groundbreaking outcomes. In the fast-paced world of electronics, the ability to quickly develop and prototype new microdevices is crucial. ATLANT 3D’s Microdevice R&D and Prototyping services offer a comprehensive solution for accelerating your product development cycle. From rapid functional device prototyping to small-batch prototyping and iteration, our team of experts will work closely with you to bring your ideas to life. We also utilize innovative direct-write technology to provide precise and flexible microdevice fabrication. The development of new and innovative materials is essential for the advancement of electronics. ATLANT 3D’s Material Innovation and R&D services provide a comprehensive approach to material research and development. We offer rapid testing of new materials to rapidly evaluate their properties and capabilities, as well as detailed analysis of material composition and characteristics to ensure high standards in material development. Furthermore, we create novel materials tailored to specific applications to meet the ever-evolving needs of the electronics industry. The integration of microdevices is a complex process that requires precision and expertise. ATLANT 3D’s Integration of Microdevices services offer a complete solution for integrating microdevices into larger systems. We incorporate sensing capabilities into microdevices to provide valuable information, modify surfaces for specific applications to enhance functionality, apply protective and optical coatings in designated areas to enhance device performance, and perform chip surgery to make precision alterations and repairs at the microscale. Exclusive inside look at ATLANT 3D’s lab, where we showcase the versatility and innovation of our in-house processes using the Direct Atomic Layer Processing (DALP®) technology. This video provides a comprehensive overview of various samples created through our advanced DALP® technology, illustrating its wide range of applications and efficiency in a laboratory setting. Our revolutionary tools are built to enhance the whole value chain of advanced micro- and nano-device manufacturing. ATLANT 3D redefining the landscape of advanced manufacturing with its pioneering NANOFABRICATOR™ series. It enables multi-material deposition in one process, tested on a wide range of advanced materials, independent of surface roughness and substrate sensitivity with multi-shape deposition and a high degree of thickness control. At our A-Lab, we are committed to pushing the boundaries of precision engineering and innovation. Whether you are considering a partnership, looking for cutting-edge solutions, or simply intrigued by the potential of atomic layer manufacturing, you’ll find the answers here. A-LAB

Your partner in microfabrication

Introducing DALP®

Revolutionizing Material Science with Our Technological Breakthrough

The R&D Powerhouse

Pioneering Research and Development

Microdevice R&D and prototyping

Material innovation and R&D

Integration of Microdevices

Video Insights

IN-HOUSE PROCESS SAMPLES

NANOFABRICATOR™ Series

Our Solutions

Questions & Answers

- Technology

OUR TECHNOLOGY

TechnologyDiscover ATLANT 3D's unique atomic layer advanced manufacturing technology based on Direct Atomic Layer Processing (DALP®).

- Solutions

OUR SOLUTIONS

All ProductsOur revolutionary tools are built to enhance the whole value chain of advanced micro- and nano-device manufacturing. Our A-HUB solutions enable rapid prototyping, pilots and feasibility studies.

- Applications

ADVANCED NANOFABRICATION

All ApplicationsOur technology is built for advanced applications enabling previously impossible functionality and speed at a fraction of the cost. Its reach across multiple application domains plays a pivotal role in propelling industries toward cutting-edge technological achievements.

- Insights

INSIGHTS

Explore insightsLearn how we are building the foundation for new advanced materials innovation and high-tech applications of the future.

RESOURCES

- About

OUR MISSION

About UsWe are building the future atomically precise advanced manufacturing technology & infrastructure for micro and nanoelectronics, optics & photonics on Earth and Beyond.

OUR COMPANY