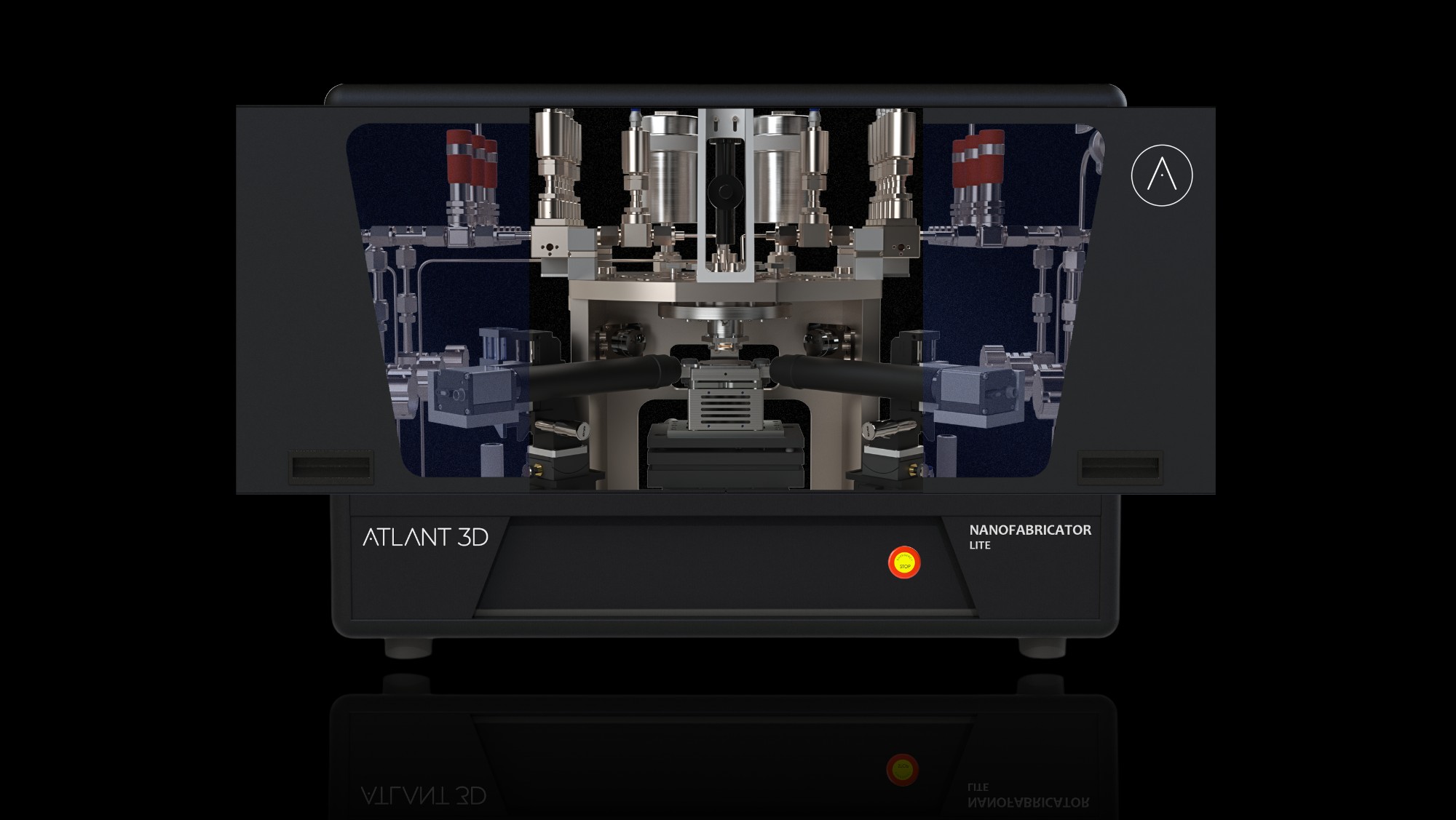

Enhancing Industry Capabilities with DALP Technology DALP™ (Direct Atomic Layer Processing) technology is reshaping semiconductor fabrication with its precision material engineering and advanced fabrication methods. It addresses the industry’s push for miniaturization by enabling the creation of smaller semiconductor components without sacrificing performance. Furthermore, DALP™ enhances device efficiency and streamlines the fabrication process, meeting the critical demands for rapid innovation and efficient production in the semiconductor industry. This technology is a key driver in advancing the capabilities and efficiency of modern semiconductor manufacturing. DALP™ technology introduces precise and efficient methodologies in the semiconductors industry, enabling the creation of ultra-thin layers essential for device miniaturization. It enhances material engineering for improved electrical and thermal performance and fosters innovative semiconductor designs with its atomic-level accuracy, meeting the industry’s need for complex and efficient microchips. Ultra-Thin Layer Fabrication: DALP™ technology allows for the creation of semiconductor components with exceptionally thin layers, critical for the ongoing trend of device miniaturization. High-Precision Material Engineering: The technology enables precise control over semiconductor material properties, facilitating the development of components with enhanced electrical and thermal performance. Innovative Semiconductor Design: DALP™ technology’s atomic-level precision opens new possibilities in semiconductor design, allowing for the development of more complex and efficient microchips. In the semiconductor industry, DALP™ technology brings enhanced component efficiency, scalability, and sustainability. Its precision engineering leads to semiconductors with superior performance, crucial in modern electronics. The technology’s adaptability ensures scalable fabrication solutions across various applications, while also promoting sustainable manufacturing practices in semiconductor production. Enhanced Component Efficiency: The precise engineering capabilities of DALP™ technology lead to semiconductors with improved performance, essential in today’s technology-driven world. Scalability and Versatility: DALP™ technology offers scalable solutions for semiconductor fabrication, adaptable to various applications and industry requirements. Sustainable Manufacturing: Emphasizing sustainable practices, DALP™ technology aids in reducing waste and improving material utilization in semiconductor production. DALP™ technology’s impact in the real world extends across multiple sectors. In consumer electronics, it enables the production of compact, high-performing microchips. For high-performance computing, it contributes to the development of efficient, fast semiconductors. In the automotive industry, DALP™ technology improves the reliability and performance of semiconductor components, essential for advanced vehicle electronics and safety systems. Advanced Consumer Electronics: In consumer electronics, DALP™ technology can facilitate the production of smaller, more powerful microchips, essential for compact and high-performing devices. High-Performance Computing: DALP™ technology contributes to the development of semiconductors for high-performance computing applications, where efficiency and speed are paramount. Automotive Electronics: In the automotive sector, the technology enhances the reliability and performance of semiconductor components used in vehicle electronics and safety systems. DALP™ technology is set to positively impact the semiconductor industry by providing advanced solutions for chip fabrication. Its focus on precision, efficiency, and sustainability aligns with the industry’s aim to meet the growing demands for advanced electronic devices and systems. By enabling the production of high-quality, efficient semiconductors, DALP™ technology is proving to be a valuable asset in driving forward the capabilities and growth of this vital industry. NANOFABRICATOR™ Lite stands as a pivotal tool, bringing a suite of innovative features that significantly enhance semiconductor manufacturing. Precise Layer Deposition: NANOFABRICATOR™ Lite excels in depositing ultra-thin layers with high precision, a critical requirement for the development of advanced semiconductor components. Material Versatility: This technology supports a wide range of semiconductor materials, offering flexibility in the fabrication of various types of semiconductor devices. Rapid Prototyping Capabilities: The ability to swiftly prototype semiconductor components accelerates the development process, enabling quicker transitions from design to production. Enhanced Component Performance: NANOFABRICATOR™ Lite’s precision layering significantly improves the performance of semiconductor devices, meeting the industry’s demand for high-efficiency components. Reduced Production Time and Costs: Its rapid prototyping capability not only speeds up the production process but also reduces associated costs, making it an economical choice for semiconductor manufacturing. Sustainability in Fabrication: Emphasizing eco-friendly production, the NANOFABRICATOR™ Lite aligns with sustainable manufacturing practices, reducing waste and improving resource efficiency in semiconductor fabrication. The NANOFABRICATOR™ Lite plays a crucial role in advancing chip manufacturing processes, enabling the production of smaller and more efficient semiconductor components that are essential for modern electronics. Its capabilities in precision and material versatility are key in driving innovation within the semiconductor industry, paving the way for the development of next-generation devices. Furthermore, the NANOFABRICATOR™ Lite not only enhances the efficiency of semiconductor manufacturing but also champions sustainable practices, aligning with the industry’s focus on environmentally responsible production methods. Semiconductors

Precision and Innovation in Semiconductor Fabrication

Key Applications in the Semiconductors Industry

Benefits of DALP™ Technology

Real-World Application Possibilities

Impact of DALP™ Technology in Semiconductors

Our Solution

NANOFABRICATOR™ Lite: Advancing the Semiconductors Industry

Innovative Features

Benefits in the Semiconductors Sector

Impact on the Semiconductors Industry

- Technology

OUR TECHNOLOGY

TechnologyDiscover ATLANT 3D's unique atomic layer advanced manufacturing technology based on Direct Atomic Layer Processing (DALP®).

- Solutions

OUR SOLUTIONS

All ProductsOur revolutionary tools are built to enhance the whole value chain of advanced micro- and nano-device manufacturing. Our A-HUB solutions enable rapid prototyping, pilots and feasibility studies.

- Applications

ADVANCED NANOFABRICATION

All ApplicationsOur technology is built for advanced applications enabling previously impossible functionality and speed at a fraction of the cost. Its reach across multiple application domains plays a pivotal role in propelling industries toward cutting-edge technological achievements.

- Insights

INSIGHTS

Explore insightsLearn how we are building the foundation for new advanced materials innovation and high-tech applications of the future.

RESOURCES

- About

OUR MISSION

About UsWe are building the future atomically precise advanced manufacturing technology & infrastructure for micro and nanoelectronics, optics & photonics on Earth and Beyond.

OUR COMPANY