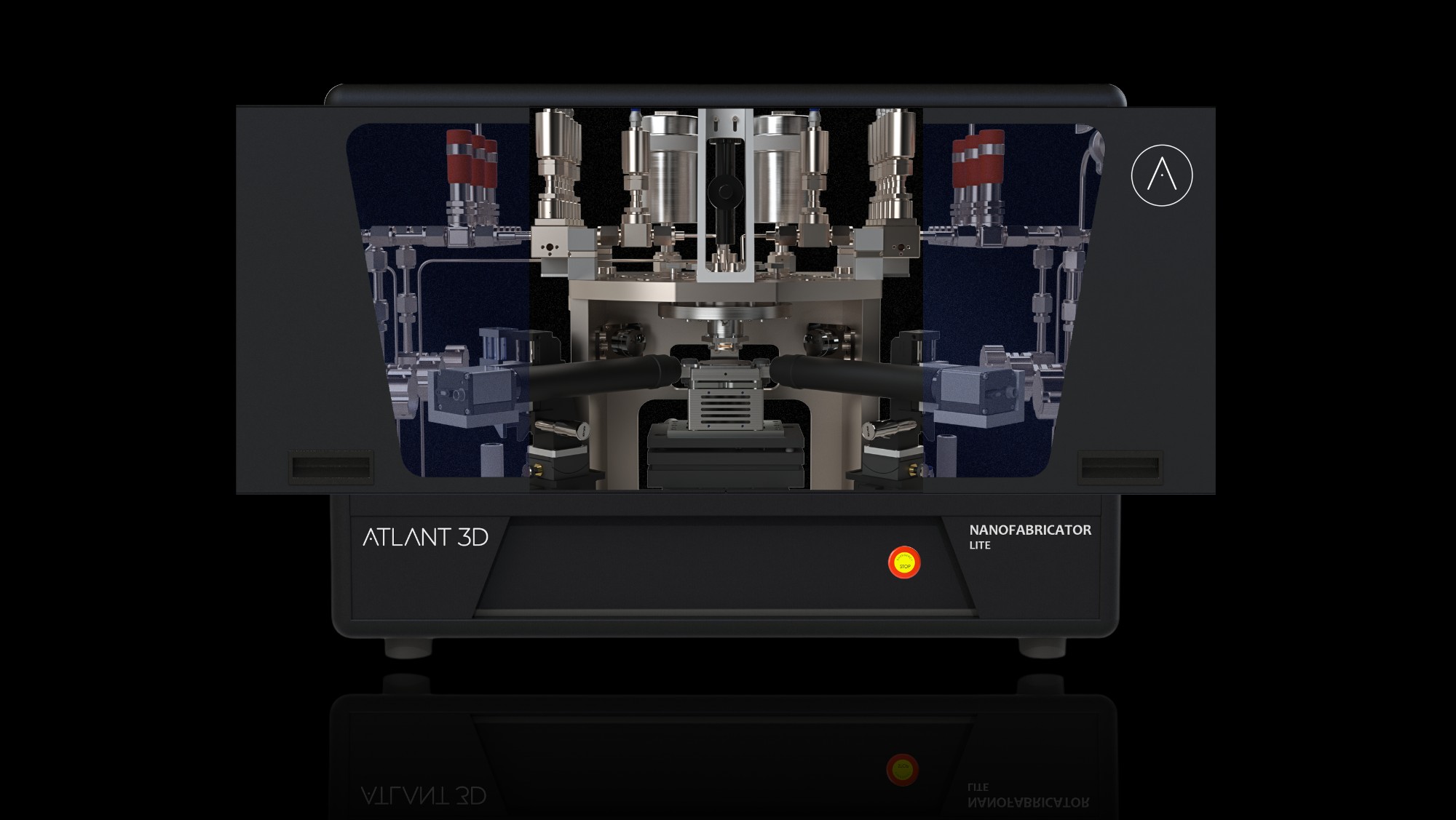

Precision-driven microfabrication for enhanced sensory technologies. Harnessing the power of nanoscale engineering to enhance microelectromechanical systems and sensor technology in a rapidly evolving digital world. In the intricate realm of MEMS (Microelectromechanical Systems) and sensor technology, ATLANT 3D is at the forefront, integrating sophisticated nanotechnology to advance fabrication processes. Utilizing our DALP™ (Direct Atomic Layer Processing) technology, embodied in the innovative Nanofabricator series, we provide solutions that cater to the nuanced demands of MEMS and sensor production. The benefits of ATLANT 3D’s approach in MEMS and sensor fabrication are multifaceted, addressing key industry challenges such as miniaturization, complexity, and performance. Our technology enables the creation of more efficient, reliable, and precise devices. Exceptional Miniaturization: Our atomic-scale manufacturing facilitates the development of ultra-small MEMS and sensors, crucial for applications requiring compact yet powerful components. Complex Geometries and Structures: The precision of our technology allows for the creation of intricate designs and complex structures, essential in the advanced functionality of MEMS and sensors. Enhanced Performance and Reliability: By improving the precision and quality of these components, we ensure higher performance and reliability, vital in critical applications across various sectors. Rapid Prototyping and Development: Accelerating the development cycle, our technology allows for faster prototyping and testing, essential in the fast-paced MEMS and sensor market. ATLANT 3D’s capabilities in MEMS and sensor fabrication are underpinned by advanced technological innovations and a commitment to quality. Our approach not only meets the current demands of the industry but also anticipates future needs. High-Resolution Layering: The Nanofabricator series offers high-resolution layering capabilities, essential for the precise fabrication of MEMS and sensors. Material Versatility: Our technology supports a wide range of materials, enabling the production of diverse types of MEMS and sensors tailored to specific applications. Customization and Adaptability: We provide customizable solutions, ensuring that each MEMS or sensor is optimally designed for its intended application. Integration with Current Technologies: Our solutions are designed to integrate seamlessly with existing manufacturing processes, ensuring a smooth transition to advanced MEMS and sensor fabrication. ATLANT 3D’s contributions to the MEMS and sensor sector exemplify our commitment to precision, efficiency, and innovation. By leveraging our advanced nanotechnology, we enable the production of smaller, more complex, and higher-performing MEMS and sensors, which are essential in today’s technology-driven world. Our approach not only enhances the capabilities of these components but also streamlines the manufacturing process, making it more cost-effective and efficient. As we continue to push the boundaries of MEMS and sensor technology, ATLANT 3D remains dedicated to delivering solutions that meet the evolving needs of industries reliant on these critical technologies. The NANOFABRICATOR™ Lite stands as a pivotal innovation in the field of MEMS & Sensor fabrication, bringing together nanoscale precision and advanced material compatibility in a compact, user-friendly design. Precision Engineering: The NANOFABRICATOR™ Lite is designed to operate with nanoscale precision, essential for the intricate work involved in MEMS & sensor fabrication. Advanced Material Compatibility: This machine is compatible with a wide range of materials, allowing for diverse MEMS & sensor applications across various fields. Customizable Processes: Offering flexibility in process parameters, the NANOFABRICATOR™ Lite can be tailored to meet specific requirements of different MEMS & sensor projects. Compact Design: Its sleek and compact design makes it suitable for laboratory environments where space is at a premium. Enhanced Product Quality: The nanoscale precision of the NANOFABRICATOR™ Lite ensures high-quality production of MEMS & sensors with improved performance characteristics. Versatility in Application: Its ability to handle various materials expands the scope of MEMS & sensor designs that can be prototyped and produced. Efficient Production: Streamlined processes and customization options lead to increased efficiency in MEMS & sensor manufacturing. Cost-Effectiveness: The reduction in material waste and energy usage translates to cost savings, making high-end MEMS & sensor production more accessible. The introduction of the NANOFABRICATOR™ Lite into the MEMS & Sensor production arena marks a significant advancement in the field. Its precision and versatility enable the creation of more complex and reliable MEMS & Sensors, which are crucial in the advancement of technologies in various sectors including healthcare, automotive, and consumer electronics. By offering a cost-effective and efficient solution, ATLANT 3D’s NANOFABRICATOR™ Lite not only enhances the quality and capability of MEMS & Sensors but also makes cutting-edge sensor technology more accessible to a broader range of researchers and developers. This democratization of advanced manufacturing tools is pivotal in driving innovation and progress in the MEMS & Sensor industry. MEMS & Sensors

Advancing MEMS & Sensors Fabrication with Precision Nanotechnology

Benefits in the MEMS & Sensors application

Capabilities of DALP™ Technology

Impact on Technology Advancement

Our Solution

Empowering MEMS & Sensor Fabrication with NANOFABRICATOR™ Lite

Innovative Features

Benefits in the MEMS & Sensors

Impact

- Technology

OUR TECHNOLOGY

TechnologyDiscover ATLANT 3D's unique atomic layer advanced manufacturing technology based on Direct Atomic Layer Processing (DALP®).

- Solutions

OUR SOLUTIONS

All ProductsOur revolutionary tools are built to enhance the whole value chain of advanced micro- and nano-device manufacturing. Our A-HUB solutions enable rapid prototyping, pilots and feasibility studies.

- Applications

ADVANCED NANOFABRICATION

All ApplicationsOur technology is built for advanced applications enabling previously impossible functionality and speed at a fraction of the cost. Its reach across multiple application domains plays a pivotal role in propelling industries toward cutting-edge technological achievements.

- Insights

INSIGHTS

Explore insightsLearn how we are building the foundation for new advanced materials innovation and high-tech applications of the future.

RESOURCES

- About

OUR MISSION

About UsWe are building the future atomically precise advanced manufacturing technology & infrastructure for micro and nanoelectronics, optics & photonics on Earth and Beyond.

OUR COMPANY