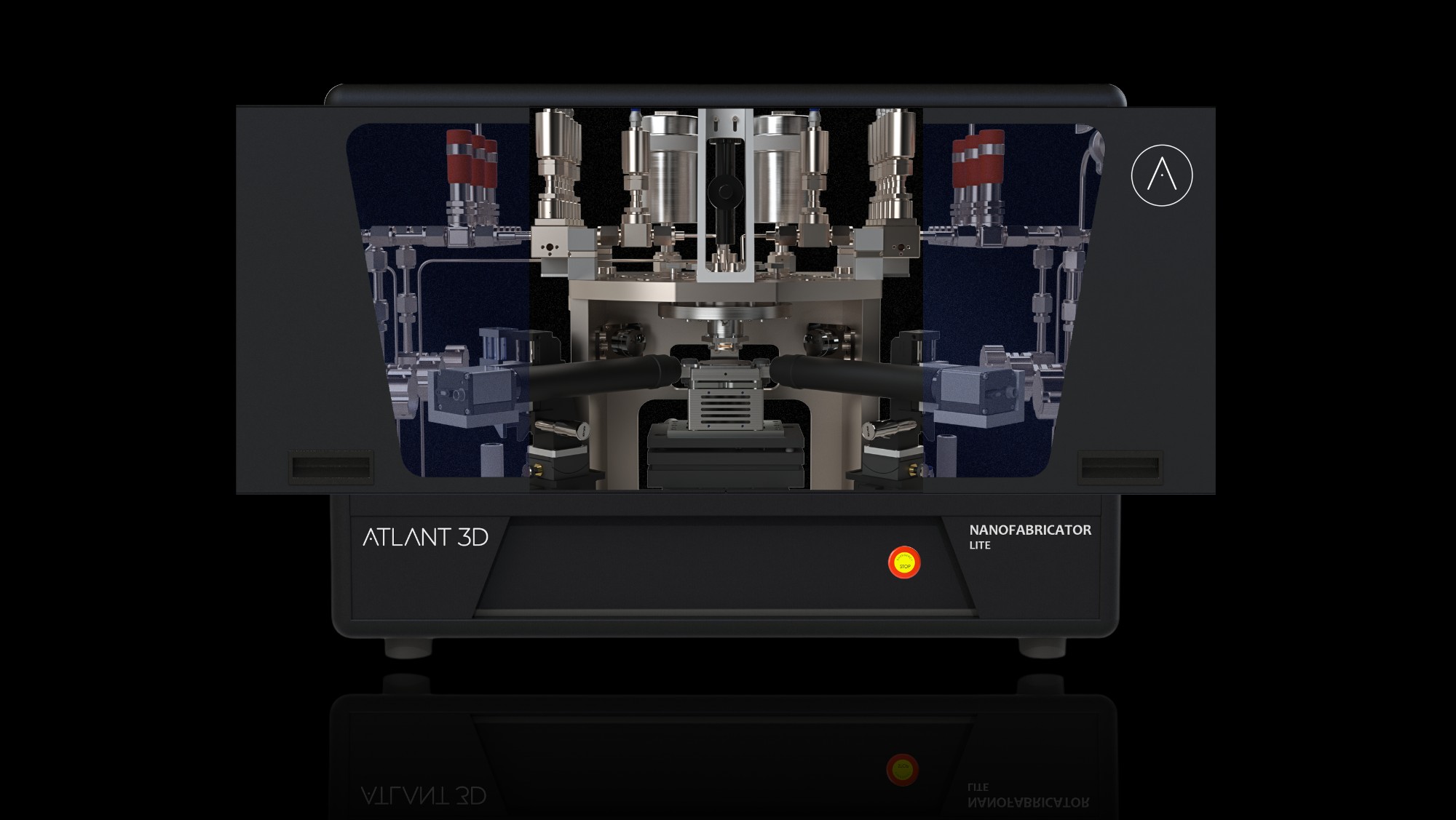

Shaping the future of mobility: nanotechnology revolutionizing automotive manufacturing, performance, and sustainability The automotive and mobility industry stands at the threshold of a transformative future, primarily driven by the burgeoning potential of advanced nanotechnology and the groundbreaking capabilities of DALP™ (Direct Atomic Layer Processing). This synergy of cutting-edge methodologies is poised to revolutionize the automotive landscape, profoundly influencing how vehicles are conceptualized, manufactured, and operated. The integration of advanced nanotechnology into automotive development is ushering in a groundbreaking era in vehicle design and manufacturing. This technological leap is set to fundamentally transform the automotive industry, bringing forth innovative solutions that align with contemporary needs for efficiency, sustainability, and performance. Innovative Material Science: The advent of advanced nanotechnology in the automotive sector promises to usher in a new wave of lightweight yet robust materials. This development is crucial in crafting vehicles that are not only more fuel-efficient but also have reduced environmental impacts. Optimized Performance and Efficiency: The fine-tuned precision and capabilities provided by these technological advancements stand to significantly elevate vehicle performance. This translates into vehicles that are faster, more responsive, and more efficient. DALP™ technology is revolutionizing the automotive industry with its groundbreaking layer-by-layer construction method. This innovative approach is not only redefining manufacturing processes but is also playing a crucial role in enhancing vehicle performance, advancing electric vehicle technology, and promoting eco-friendly manufacturing practices, marking a significant stride towards sustainable automotive solutions. Redefining Manufacturing Processes: DALP™ technology, with its precise layer-by-layer construction method, offers a novel approach to automotive manufacturing. This process is instrumental in enhancing vehicle performance and aligning production with sustainable practices. Advancing Electric Vehicle Technology: In the realm of electric mobility, DALP™ technology is particularly impactful in the development of advanced battery systems. These innovations could lead to electric vehicles with extended ranges, faster charging times, and overall improved energy management. Eco-Friendly Manufacturing and Sustainability: The application of our technology in vehicle production aligns seamlessly with global sustainability goals. By reducing waste and optimizing resource use, this technology underscores the industry’s commitment to environmental stewardship. As the automotive and mobility sector embarks on this journey of transformation, the combined potential of advanced nanotechnology and DALP™ technology is set to be a cornerstone of this evolution. These technologies are not just driving improvements in vehicle design and performance; they are also paving the way for more sustainable manufacturing processes and eco-friendly vehicle solutions. In this new era, the industry is poised to strike a harmonious balance between innovation, efficiency, and environmental responsibility, steering towards a future where automotive excellence and sustainability are inextricably linked. In the dynamic field of automotive and mobility, the NANOFABRICATOR™ Lite emerges as a pivotal tool, offering an array of solutions and benefits catered to this industry’s specific needs. Precision Material Fabrication: The NANOFABRICATOR™ Lite excels in creating advanced materials with unparalleled precision. Its ability to manipulate materials at the atomic level allows for the development of lightweight yet strong components, ideal for automotive applications. Enhanced Battery Development: It offers innovative solutions for electric vehicle batteries, leading to improvements in energy density and charging efficiency. Customizable Manufacturing: With its versatile capabilities, the NANOFABRICATOR™ Lite can be tailored for a wide range of automotive applications, from prototypes to large-scale production. Fuel Efficiency and Sustainability: By developing lighter materials, it contributes to increased fuel efficiency and reduced emissions in traditional vehicles. Reliability and Quality: Its precision manufacturing ensures high-quality components, enhancing the reliability and longevity of vehicles. Enhancing Battery Technology: The tool is instrumental in developing advanced materials for electric vehicle batteries, contributing to longer battery life, faster charging times, and overall improved performance. Customizable Applications: The versatility of NANOFABRICATOR™ Lite allows for tailored applications in the automotive sector, ranging from prototype development to full-scale production, ensuring solutions that meet specific industry demands. Eco-Friendly Production: Aligning with the industry’s shift towards sustainability, NANOFABRICATOR™ Lite supports environmentally conscious manufacturing processes, reducing waste and energy consumption. Automotive

Shaping the Future of Automotive & Mobility with Advanced Nanotechnology and DALP™

Integrating Advanced Nanotechnology in Automotive Development

The Transformative Role of DALP™ Technology

The Future Outlook: A Synergy of Innovation and Sustainability

Our Solution

Empowering Innovation in Automotive and Mobility with NANOFABRICATOR™ Lite

Innovative Features for Automotive

Key Benefits of NANOFABRICATOR™ Lite in Automotive and Mobility

Impact in Automotive Industry

- Technology

OUR TECHNOLOGY

TechnologyDiscover ATLANT 3D's unique atomic layer advanced manufacturing technology based on Direct Atomic Layer Processing (DALP®).

- Solutions

OUR SOLUTIONS

All ProductsOur revolutionary tools are built to enhance the whole value chain of advanced micro- and nano-device manufacturing. Our A-HUB solutions enable rapid prototyping, pilots and feasibility studies.

- Applications

ADVANCED NANOFABRICATION

All ApplicationsOur technology is built for advanced applications enabling previously impossible functionality and speed at a fraction of the cost. Its reach across multiple application domains plays a pivotal role in propelling industries toward cutting-edge technological achievements.

- Insights

INSIGHTS

Explore insightsLearn how we are building the foundation for new advanced materials innovation and high-tech applications of the future.

RESOURCES

- About

OUR MISSION

About UsWe are building the future atomically precise advanced manufacturing technology & infrastructure for micro and nanoelectronics, optics & photonics on Earth and Beyond.

OUR COMPANY