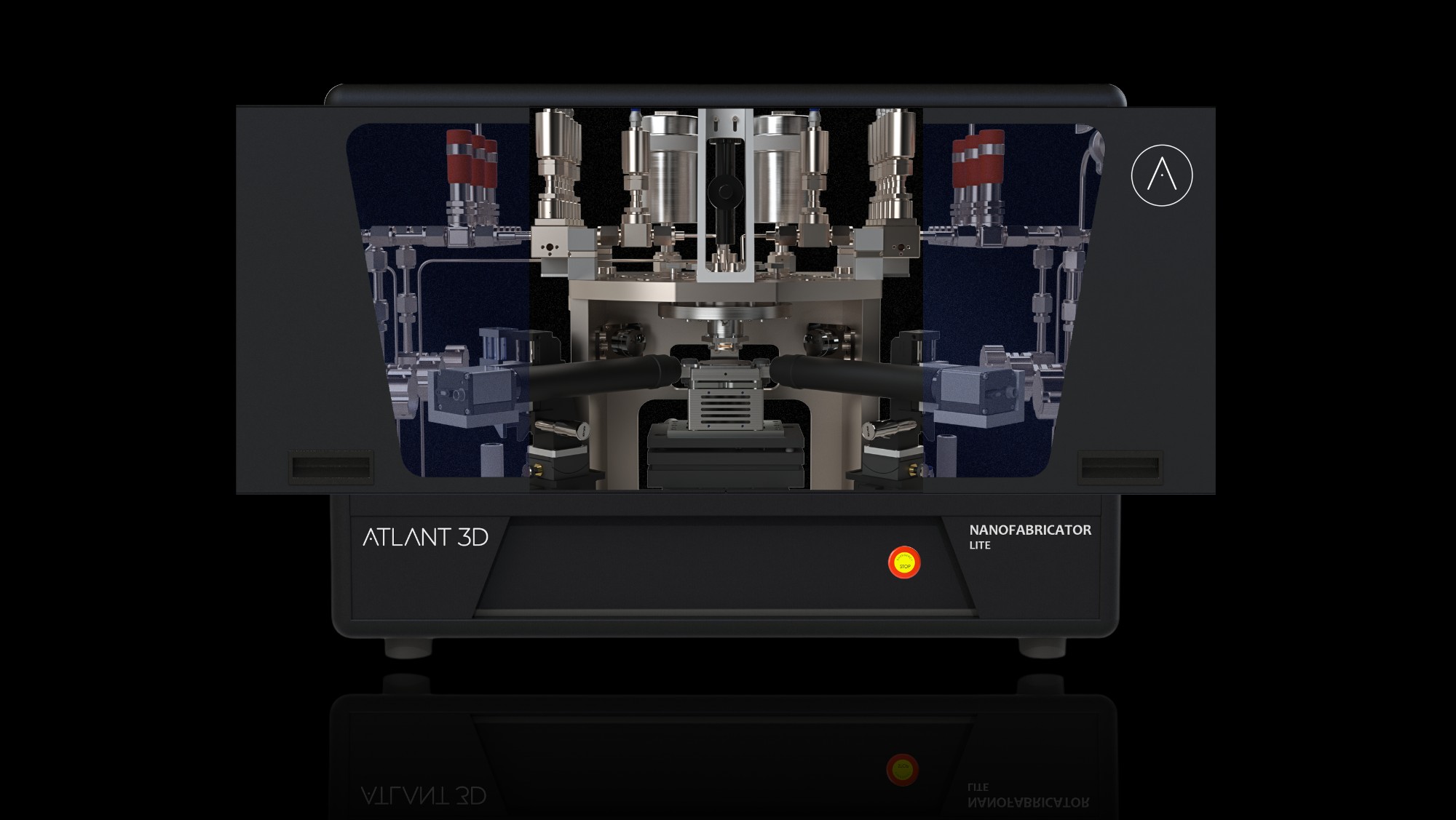

Advanced Materials are materials that are specifically engineered to exhibit novel or enhanced properties that confer superior performance relative to conventional materials. In the Advanced Materials industry, the practical application of ATLANT 3D’s μDALP™ (Micro Direct Atomic Layer Processing) technology is making a tangible impact. This technology is crucial in developing materials with enhanced precision and specific properties to meet the rigorous demands of various sectors. In microelectronics, μDALP™ facilitates the production of smaller, more efficient components, addressing the industry’s push for miniaturization. The renewable energy sector benefits from improved material efficiency in energy conversion and storage solutions. In the medical field, the technology’s precision enables the development of advanced drug delivery systems, improving treatment outcomes. ATLANT 3D’s technology thus represents a pragmatic step forward in material science, offering realistic solutions to current industry challenges. ATLANT 3D’s μDALP™ technology is significantly impacting the Advanced Materials industry with applications in electronics, energy, and biomedicine. It enables the production of ultra-thin, high-performance components in electronics and photonics, aligning with the miniaturization trend. In energy, μDALP™ enhances materials for batteries and solar cells, promoting sustainable energy solutions. Additionally, its precision in the biomedical field is crucial for developing targeted drug delivery systems and diagnostic devices, advancing medical research and applications Electronics and Photonics: μDALP™ technology enables the development of ultra-thin, high-performance electronic and photonic components. By allowing precise control at the atomic level, it is possible to create components with improved efficiency and smaller sizes, vital for the miniaturization trend in electronics. Energy Storage and Conversion: In the field of energy, μDALP™ is instrumental in developing advanced materials for batteries and solar cells. These materials enhance energy density, efficiency, and lifespan, contributing to more sustainable and effective energy solutions. Biomedical Applications: The technology’s precision is revolutionizing biomedical research, particularly in drug delivery systems and diagnostic devices. By enabling the creation of nanoscale features, it facilitates the development of more targeted and efficient medical applications. Our technology has enabled the development of materials with customized properties such as enhanced strength, conductivity, and reactivity, meeting diverse and specific industry requirements. Its capability for atomic-level manipulation has opened new avenues in material design and fabrication, allowing for the creation of previously unimaginable materials and structures. Enhanced Material Properties: Research in μDALP™ technology has led to materials with tailored properties, including improved strength, conductivity, and reactivity. This customization is crucial in meeting specific industry needs. Innovative Design and Fabrication: The ability to manipulate materials at the atomic level opens up innovative design possibilities, leading to the creation of materials and structures that were previously impossible. Sustainability and Efficiency: μDALP™ technology promotes sustainable practices in material development. By reducing waste and enhancing material efficiency, it aligns with environmental goals and improves the overall sustainability of manufacturing processes. ATLANT 3D is leading a significant transformation in advanced material development with its μDALP™ technology. This technology is not just progressing the field of material science but redefining possibilities across multiple industries, from microelectronics and renewable energy to medicine. By enabling the creation of smaller, more efficient semiconductors, enhancing solar panel efficiency, and revolutionizing drug delivery systems, μDALP™ technology is setting new standards in these sectors. ATLANT 3D’s innovative approach goes beyond overcoming existing limitations, focusing on groundbreaking materials that are crucial for technological advancement and sustainability. This broad spectrum of applications highlights μDALP™ technology’s crucial role in advancing material science, demonstrating its potential to redefine industry benchmarks and lead the way in future developments. In the rapidly evolving Advanced Materials industry, ATLANT 3D’s NANOFABRICATOR™ Lite stands out as a key tool that brings a new dimension of innovation and capability. This advanced technology is particularly tailored to meet the unique demands of developing materials for challenging environments. Ultra-Precision Fabrication: NANOFABRICATOR™ Lite stands out with its ability to construct materials atom by atom, offering unmatched precision. This feature is crucial for developing materials with highly specific properties, essential in advanced applications. Broad Material Compatibility: The tool’s versatility in processing a wide array of materials, from metals to polymers, makes it an invaluable asset in the diverse field of advanced materials. Customizable Material Development: NANOFABRICATOR™ Lite allows for extensive customization in material composition and structure, facilitating the creation of novel materials tailored to unique industry requirements. Enhanced Material Properties: The precision of NANOFABRICATOR™ Lite leads to the development of materials with superior properties, such as increased strength, durability, or conductivity, vital for challenging applications. Cost-Effective Innovation: Offering an economical alternative to traditional methods, it enables more widespread research and development efforts in the advanced materials sector. Efficiency and Sustainability: By optimizing material usage and reducing waste, NANOFABRICATOR™ Lite aligns with sustainable manufacturing practices, crucial in today’s environmentally conscious world. The introduction of NANOFABRICATOR™ Lite marks a pivotal revolution in material science, unlocking new possibilities for creating advanced materials previously beyond the realm of possibility. Its profound impact transcends various industries reliant on advanced materials, including aerospace, biotechnology, and renewable energy, catalyzing significant innovation and progress. Furthermore, the tool’s commitment to eco-friendly practices not only elevates the standard of material development but also plays a crucial role in steering these industries towards a more sustainable future. Advanced Materials

Tackling the Limitations of Conventional Material Development

Key Applications of μDALP™ Technology in Advanced Materials

Research and Benefits of μDALP™ Technology

Real-World Applications and Innovations in Material Science

Our Solution

Transforming the Advanced Materials Industry

Innovative Features of NANOFABRICATOR™ Lite

Benefits in the Advanced Materials Sector

Impact on the Advanced Materials Industry

- Technology

OUR TECHNOLOGY

TechnologyDiscover ATLANT 3D's unique atomic layer advanced manufacturing technology based on Direct Atomic Layer Processing (DALP®).

- Solutions

OUR SOLUTIONS

All ProductsOur revolutionary tools are built to enhance the whole value chain of advanced micro- and nano-device manufacturing. Our A-HUB solutions enable rapid prototyping, pilots and feasibility studies.

- Applications

ADVANCED NANOFABRICATION

All ApplicationsOur technology is built for advanced applications enabling previously impossible functionality and speed at a fraction of the cost. Its reach across multiple application domains plays a pivotal role in propelling industries toward cutting-edge technological achievements.

- Insights

INSIGHTS

Explore insightsLearn how we are building the foundation for new advanced materials innovation and high-tech applications of the future.

RESOURCES

- About

OUR MISSION

About UsWe are building the future atomically precise advanced manufacturing technology & infrastructure for micro and nanoelectronics, optics & photonics on Earth and Beyond.

OUR COMPANY